Be it picking of goods or barcode scanning, technological changes have brought about considerable improvements in the way warehouses run. Yet many challenges act as roadblocks to optimum efficiency. Warehouses are not meant for storing goods. It also has employees who perform specific tasks regularly. The market for global warehouse solutions can grow from $3.94 billion this year to $13.34 billion by 2030. The market is projected to expand at a compound annual growth rate (CAGR) of 19%.

Efficient logistics is the cornerstone of a successful business. Be it procurement or production, inventory management or shipping, each aspect of the logistics process needs to function seamlessly to ensure timely delivery of goods. However, there are a number of challenges that warehouses face daily. Some of these challenges are mentioned below –

3 Major Challenges Associated with Warehouse and Inventory Management

1. Overstocking and Stockouts

Initial procurements do not comprise the only expenses that companies incur while overstocking goods. When goods lie in a warehouse for days, they occupy space and also tie up capital that could be invested in another area. Moreover, perishable goods can get spoiled within days.

On the other hand, stockouts signify missed opportunities for revenue generation. The lack of inventory can hurt the trust of customers, who may opt for your competitors. So, you don’t just miss out on an opportunity to sell but also lose potential customers.

2. Inefficient Use of Space

Product stacking is very easy. But how to make efficient use of space? Effective warehouse management maximizes space, ensuring judicious use of each square inch. Moreover, when products are placed without proper layout, retrieval times will be longer. So, inefficiency can block the flow of goods, reducing bandwidth and impacting service quality.

3. Weak Labor Allocation Planning

During demand fluctuations, understaffing can cause delays and overexertion. Overstaffing on the other hand can inflate the cost of labor. The right manpower size is not enough, they need to be strategically positioned. The location of an employee can have a significant impact on production, be it restocking or order picking.

Ready to optimize your warehouse operations? Discover the power of our Warehouse and Inventory Management System today!

How do AI and ML resolve these challenges?

According to a McKinsey report, AI-driven warehouse inventory management system can boost efficiency by up to 30%. This improvement is because of optimized management of inventory, picking, packing as well as shipping processes. The report also stated that automation can help your company minimize labor costs by 40%. You can rely on AI-powered robots to perform repetitive tasks, while your staff work on more urgent tasks.

“According to the 2024 MHI Annual Industry Report, 74% of leaders within the supply chain industry are increasing their investments in the technical domain. 90% have stated that they will invest more than $1 million.”

14 Ways Through Which AI Solutions Can Resolve The Above Mentioned Challenges

1. Improved Use of Space Through Smart Layouts

Static layouts with warehouses often cause inefficiencies, especially when there is a change in product demand. AI-driven algorithms can reevaluate product placements using real-time sales data, incoming stock, and seasonality. Enhanced space usage will ensure that high-demand products are always within easy reach, reducing retrieval times.

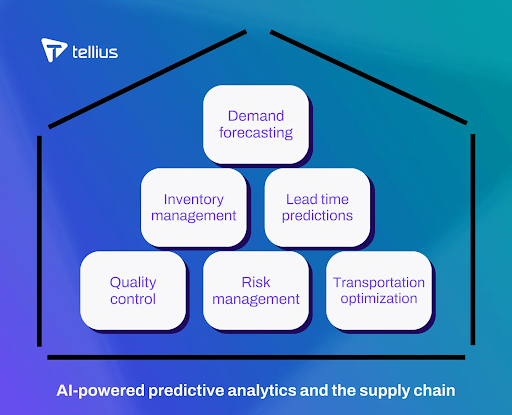

Source: Tellius

2. Use Predictive Analytics For Optimized Inventory Levels

So far, inventory management has been heavily dependent on historical data. This approach in some cases fails to detect unforeseen changes in the market or consumer behavior. Using predictive analytics, a branch of ML, warehouses can foresee demand shifts beyond sales, based on social media patterns and market trends. This means the more accurate the stock levels, the lesser will be the holding costs and stockouts.

3. Accurate Demand Forecasting

Traditional tools of demand forecasting might not focus on global events or sudden changes in the market. You can use deep learning models, a subset of ML, and share vast, diverse data sets, starting from global news to industry-specific updates. They can accurately spot patterns that people often miss out on and offer more precise demand predictions.

4. Ensuring Cost Efficiency

Manual processes, even when supported by software can be error-prone and time-consuming. You can rely on AI-driven automation to handle daily tasks like billing and order processing. This will reduce operating costs and minimize human errors, enhancing the efficiency of warehousing operations.

5. Enhanced Productivity

While you and your coworkers can rigorously oversee tasks, integrating AI warehouse solutions for detection, tracking, and optimization can help you focus on other areas. Consider AI as a guide to enhance your productivity while you focus on strategic planning and building client relationships. You can rely on warehouse inventory management system for monitoring and optimizing cycle & lead times, quantities, temperatures, errors, and downtime planning.

6. Better Warehouse Management

Using AI for inventory management enhances warehouse efficiency by minimizing errors and reallocating tasks to staff efficiently. Cloud-based warehouse optimization software helps to ensure swift, perfect communication, improving logistics tasks such as pallet counting and reduces processing time. It helps to ensure real-time monitoring of inventory levels, enhancing the efficiency of warehouse operations.

Warehouse optimization software can communicate accurate information more quickly than individuals. Implementing cloud-based devices enables instant and on-the-move updates to be shared. You can rely on AI to optimize logistics tasks like pallet counting, minimizing processing time and the risks of human error.

7. Use Predictive Analytics To Minimize Downtime

Predictive analytics is a very useful tool for decision-making, as it enables warehouse managers to make data-driven decisions with good insights. This cost-effective solution uses predictive analytics to help you detect anomalies and failure patterns, learn from them, and also predict issues of failure in the future. This lowers downtime as you can prevent the predicted problems before they occur.

8. Automated Material Procurement

Procurement is a vital aspect of the production process. It needs both supplies and equipment. This process often involves managing numerous suppliers and documents. Therefore, inefficiencies and errors are likely to crop up. Streamlining the procurement process by using automation can reduce these challenges, and boost efficiency and accuracy throughout the supply chain.

9. More Effective Marketing Strategies

One major plus point of AI-enhanced inventory management is that it offers good insights that can help a company create workable marketing strategies. AI and ML can highlight the short-term demand for products and also their market. You can spot sporadic changes in product interest using smart inventory tools like machine-learning-based anomaly detection and AI.

Source: GEP

10. In-Warehouse Travel Optimization

Warehouse workers spend a greater part of their day traveling within the warehouse. Therefore, travel reduction is the key to enhanced productivity. Automation and robots can eliminate the need for traveling, and AI can be used in those areas where automation isn’t enough. AI and ML use large volumes of processed data to ‘learn’ how priorities can be balanced and minimize travel via intelligent order batching and pick sequencing.

11. Dynamic Slotting

Optimizing product placement is essential for efficiency, accuracy and proper use of resources in warehouses. But this task is complicated, with various factors and opposing objectives that need to be balanced. AI-driven inventory management helps to streamline this process by automating manual tasks and also adapting to changing conditions, ensuring improvement in performance.

Source: SDC Supply & Demand Chain

12. Back-Office Operations

Back-office operations are an important part of any business, including logistics. AI plays an important role in enhancing the accuracy and speed of most back-office operations. By combining Robotic Process Automation(RPA) with AI, businesses are using something new called cognitive automation. This enables staff to enhance accuracy and productivity in different repetitive tasks, like billing and procurement.

13. Ensure Faster Shipping

In a conventional warehouse, order processing takes a long period. Workers spend a lot of time picking orders and filling orders. AI-based warehouse solutions can eliminate all picking errors. Automated robots minimize order-picking time and ensure that workers don’t have to be on the move all the time. This helps to speed up the order shipping process.

14. Storage Optimization

Storage optimization is a major factor in minimizing costs for scale-driven businesses. Warehouses that have automated their storage processes with AI outperform those that follow a traditional model. Making decisions on lean storage use requires know-how about storage units, assets, contains, and also shipping fleet.

Role of AI in Modernizing Warehouse Management

1. Better Quality of Customer Support

- Chatbots are on the rise and a warehouse inventory management system is no exception to it. You can use AI chatbots to be updated about your ERP inventory system and keep track of orders.

- For instance, you can ask a chatbot to share a lowdown related to a specific order. It will make it easy for your staff to focus on other activities.

- The use of voice-based chatbots is becoming more and more popular. According to Statista’s predictions, there will be more than 157 million voice assistant users in the US alone by 2026.

Are you looking for a Transport Management System that can automate administrative tasks like order processing? Talk to our experts.

2. Automation of Document Processing

- To accurately add information from vendor documentation, receive invoices, and product labels within backend systems, manual labor and understanding of the job are needed.

- Most warehouses process these documents regularly, making employees defer work on more time-constrained and important tasks.

- You can rely on machine learning to extract valuable details from these documents. This is done by an automated document processing software, which automatically updates datasets and backend systems.

Source: AltexSoft

3. More Safety

- One major plus point of the AI-based warehouse solutions is safety. AI solutions can help you track operations and also rate the risk of different warehouse activities. AI-powered robots can perform dangerous tasks, freeing your staff to work on safer activities.

- Moreover, you can train your staff in using standard operating procedures using AI solutions using a combination of AR and VR devices to minimize instances of physical injury.

4. Damage Detection

- AI technology can help you to identify damages in various ways. It can help you to identify the type of damage, its extent, and how it can be reduced before it causes more harm.

- Opting for AI-powered inventory and warehouse solutions can increase the effectiveness of freight train wagons and guard against damage to ensure continuous usage.

- Software is programmed for retrieving data from cameras placed along train lines to perform the operations. These cameras record photos of the wagons and utilize AI vision technology for processing them. This consequently improves accuracy and minimizes damage to the wagons.

5. Accuracy

- Precision is essential to improve efficiency. Using AI warehouse technology can help you to manage and operate warehouses with a high level of efficiency. AI robots are capable of sorting, arranging, moving, stocking, and retrieving goods in the inventory with precision.

- To boost operational efficiency, warehouses can utilize new technologies such as machine learning, IoT, and computer vision along with AI.

Source: Matellio

6. Quicker Fulfillment Cycles

- Employees working in a nonautomated warehouse have to move a lot to search for different products. This takes a lot of time and there are often mistakes.

- The time required to look for a product, confirm, and pick it up from a storage container can be greatly reduced by making use of smart picking devices such as portable scanners, picking robots, pick-to-light, and wearable technology.

- They can therefore save packages from getting mislabeled and mislabeled in the same way as conveyors and parcel sorters. So, quicker selection and carefree delivery can minimize the lead time of orders.

7. Distribution of Work

- AI-powered inventory and warehouse solutions can help warehouse managers in manpower distribution by evaluating the existing condition of the warehouse and also its possible future demands. It can predict large orders, detect when equipment is broken.

- AI can also identify which worker is more qualified for a specific task and allocate it to them. You’ll be able to use your existing personnel more efficiently, reducing the need to hire more workers.

How ROCKEYE Can Help Modernize Your Warehouse Management with Smart WIM Solutions?

Our warehouse solutions will help you to oversee and optimize inventory seamlessly. You will be able to track stocks, monitor movements and also streamline replenishment. Our software solutions enhance efficiency and provide real-time insights to ensure long-term success.

Using our warehouse and inventory management software, you will be able to manage stock and requests in a hassle-free manner. These solutions help to improve the supply chain and maximize control.

Conclusion

AI is a new technology that can alter the way warehouse operations are done altogether. The accuracy of procedures and existing levels of production can only be increased through the use of technology. AI helps to enhance safety standards in buildings and lower operational costs.

There are numerous areas of warehouse operations where AI can be applied. Organizations need to find ways to use AI-powered warehouse solutions in their daily operations. It can help you to achieve the long-term goals of an organization and ensure long-term operational efficiency.

FAQs

1. What are the most widely AI-driven technologies used in warehouse management?

Some of the most widely used AI-driven technologies in warehouses are Predictive Analytics which is used for demand forecasting and inventory optimization and Autonomous Guided Vehicles (AGVs).

2. Is AI implementation in warehouse management expensive?

Initial costs usually vary based on the scale and complexity of AI solutions. However, warehouse solutions offer long-term benefits by enhancing scalability and flexibility of warehouses.

3. How can AI be integrated into the existing systems of warehouses?

Warehouses can integrate AI within existing systems in two ways. Either a company can collaborate with a technical services provider with expertise in developing warehouse management solutions or build capabilities in-house.

4. How can AI improve the decision-making process of warehouse managers?

Warehouse managers can use AI to acquire real-time insights, detect deviations and create optimized strategies. It processes large volumes of data from various sources for tracking trends, patterns and potential issues.

5. Can AI improve the safety of warehouses?

Yes, AI can be used to improve safety within warehouses through the use of predictive analytics to detect the probable safety hazards. It does so through the use of historical data analysis and offers suggestions to reduce risks.

Ready to Revolutionize Your Inventory & Warehouse Operations With Automation?

Get in touch with the experts of ROCKEYE.

Request a Call