In the hustle and bustle of running warehouses, fundamental flaws of operations can be missed. Understandably, managers can misplace their focus on fixing problems as they arise, rather than identifying the cause. By taking the time to stand back, you can review warehouse KPI reports to identify key weaknesses and implement solutions.

Which Warehouse KPI to Focus On?

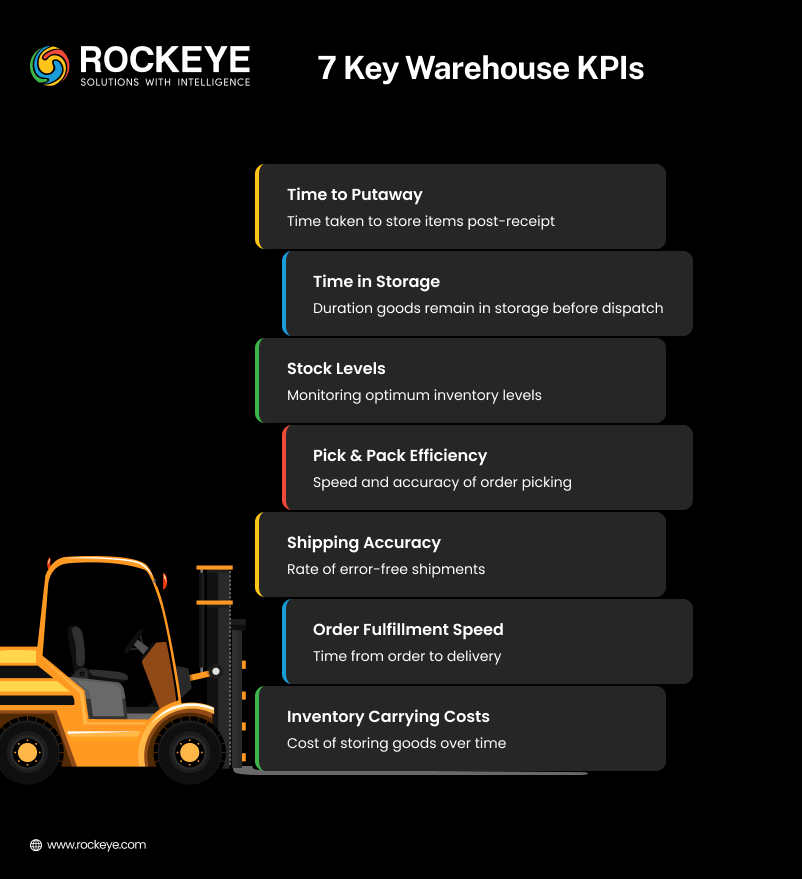

When putting together a strategy to analyze and monitor the performance of warehouse and inventory management operations, the first step should be to identify the KPIs. There are hundreds of potential KPIs in warehouse operations – and it’s impossible to track each one efficiently. Therefore, it makes sense to create a shortlist of critical metrics.

There are seven key warehouse management KPIs:

- Time to Putaway

- Time in Storage

- Stock Levels

- Pick and Pack

- Shipping Accuracy

- Order Fulfillment

- Inventory Carrying Costs

While these warehouse management KPIs form the bulk of warehouse operations, there are additional metrics to consider, including security and integration. For example, the number of items lost to theft or the level of duplicates across multiple platforms. Flexibly applying these KPI reports to the different processes will allow your business to build an accurate picture of overall performance.

Whether it’s part of an audit or a weekly review, these performance reports should be integral to any ambitious company. It provides an opportunity to improve operations, increase efficiency, and protect your business.

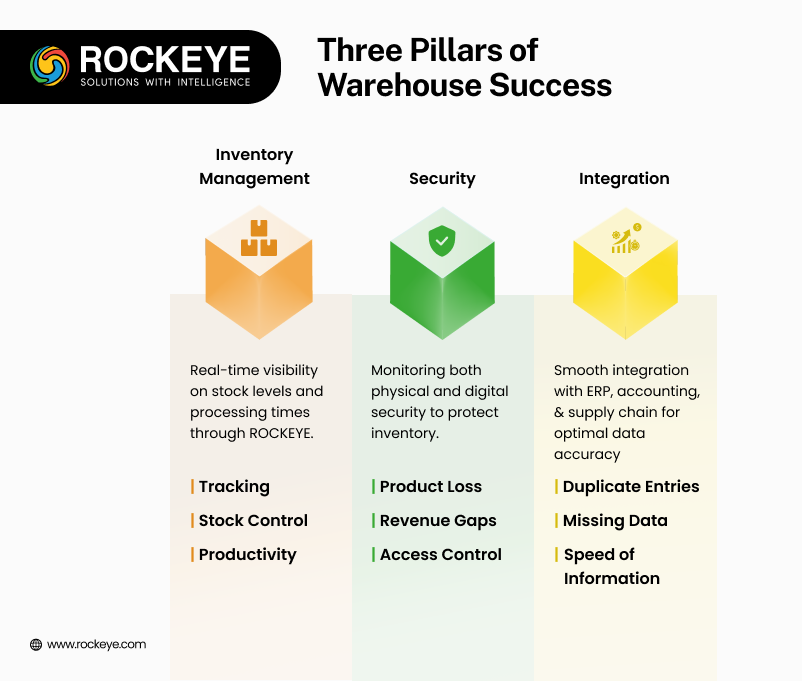

Inventory Management

The primary purpose of warehouses is to handle the storage and movement of goods. Therefore, it is critical to continually monitor and analyze inventory management, which forms the heart of warehouse operations. Identifying any flaws here can have a significant impact on business performance and profit margins. The key elements to focus on include:

- Tracking: It’s essential to be able to track inventory as it moves through warehouses. By utilizing real-time visibility offered by ROCKEYE’s solution, managers will be able to identify any weak points. For example, tracking shipping performance metrics can give a good insight into delivery accuracy. Tracking inventory as it moves through the warehouse could also be a good indicator of efficiency and time it takes to pick and pack items,

- Stock control: Having too little or too much stock can have a damaging effect on your business’s bottom line. Getting the balance right is critical for warehouses, and monitoring inventory levels should be a crucial part of operations.

- Productivity: One of the key benefits of technology is its ability to increase the productivity of teams. For instance, RFID scanning can help workers locate and pick products quicker, freeing up more hours each week for capacity growth. Being able to measure the time it takes for workers to complete tasks can help warehouse managers optimize processes, leading to an increase in revenue.

The objective of inventory control is to process products as accurately and efficiently as possible. By focusing on the three core elements, managers will be able to analyze the data in real-time through ROCKEYE’s cloud-based WMS. Workers can then quickly make alterations and changes to improve operations further and deliver results.

Security

A vital part of a successful warehouse is ensuring a high level of security. In the digital age, threats can as likely be cybercrime as much as inventory theft, and companies must take a holistic approach to protect their businesses. The KPIs in this aspect of operations may not be as clear cut as inventory management, but it is no less important.

Also Read: Purchase Order vs Invoice: Key Differences and Why They Matter

Reviewing warehouse security involves looking at several different elements, such as product loss, unexpected gaps in revenue, and accessibility. One of the main advantages of cloud-based solutions is its ability to track both inventory and worker behavior. Using WMS, managers can continually review inventory levels and monitor their movement, alerting them to unusual activity.

The other element of security is enabling secured access to warehouse systems. At ROCKEYE, we allow administrators to retain complete control over which information workers can see and use. For instance, pick and pack teams require a different set of details than those involved in the receiving and putaway process.

Being able to monitor and control access to workers can give managers complete oversight on security. Using weekly or monthly KPI reports, warehouses will be able to identify and cover any gaps.

Integration

As a cloud-based solution, ROCKEYE’s WMS is designed to integrate with third-party systems such as ERP, shipping, and accounting software. It can also operate with external stakeholders in the supply chain, enabling a smooth flow of information and inventory.

Monitoring multiple systems can be a complex undertaking. However, by focusing on a few key metrics, managers will be able to get a good picture of how well integrations are working:

- Duplicate Entries: A common issue with the integration of different systems is duplicate entries, which can add confusion for workers and lead to inventory errors.

- Missing Data: As well as duplicates, data, and information can go missing between multiple systems, which can impact inventory accuracy.

- Speed of Information: An essential component of successful integrations is how quickly workers can access information. For instance, a reputable WMS will work with scanning systems that can instantly provide the required details on specific items.

Measuring those metrics against industry averages will provide a good indication of how well the integrated systems are working. An excellent example of where it makes a difference is the integration of accounting and WMS. It’s essential to avoid any confusion over billing and shipping addresses, and a smooth integration will help to prevent such issues.

Utilize KPIs to Spark Growth

The purpose of using KPIs is to analyze the overall performance of warehouse operations. It’s essential for managers to focus on retaining its strengths while striving to improve some of the more underperforming areas. By using ROCKEYE’s cloud-based solution, companies can monitor key metrics in real-time, enabling greater flexibility and responsiveness.

In proactively analyzing the KPIs, warehouses have the opportunity to streamline processes, increase productivity and guarantee security. Each of these elements can contribute to growing revenue and higher profit margins.

FAQs

Why should warehouses use KPI reports?

KPI reports help warehouse managers identify weaknesses in their operations by tracking critical metrics. This allows them to address underlying issues proactively rather than just responding to immediate problems, which improves overall efficiency and security.

Which KPIs are essential for warehouse inventory management?

- Some key KPIs for inventory management include:

- Time to Putaway

- Time in Storage

- Stock Levels

- Pick and Pack Time

- Shipping Accuracy

- Order Fulfillment Rate

- Inventory Carrying Costs

These KPIs give a clear picture of efficiency, costs, and performance in inventory handling.

How does monitoring inventory management KPIs impact warehouse performance?

Effective tracking of inventory KPIs helps warehouses balance stock levels, improve tracking accuracy, and boost productivity. Real-time data enables swift adjustments to operations, which improves efficiency and supports capacity growth.

What role does security play in warehouse KPI tracking?

Security KPIs monitor product loss, accessibility, and worker activity, which are crucial for reducing theft and cybersecurity risks. Cloud-based WMS systems can track inventory movement and worker access, helping managers detect unusual activity early on.

How can Warehouse KPI tracking improve integration with other systems?

KPIs related to integration help identify issues like duplicate entries, missing data, and data transfer speed between systems. Effective integration between WMS, ERP, and other systems streamlines workflows, reduces errors, and ensures smooth information flow.

- cloud-based WMS

- inventory carrying costs

- inventory flaws

- inventory management

- inventory tracking

- KPI reports

- order fulfillment

- pick and pack time

- productivity improvement

- real-time data tracking

- shipping accuracy

- stock control

- time to putaway

- warehouse efficiency

- warehouse integration

- warehouse KPI

- warehouse operations

- warehouse performance

- warehouse security