The e-commerce industry has grown by leaps and bounds, backed up by the increased use of the internet. But to ensure long-term customer satisfaction, logistics companies are looking for new ways to ensure that the ordered items reach their destination safely and on time.

The Global “Artificial Intelligence in Inventory Management market” is projected to grow annually by 6.3% (CAGR 2024 – 2031). In this blog, we discuss the different ways in which IoT and AI inventory management solutions are changing the day-to-day running of warehouses –

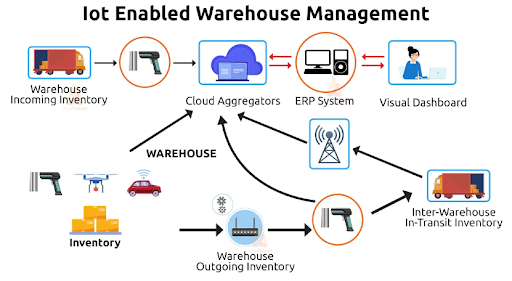

Role of IoT in Warehouse Management

The Internet of Things refers to an interconnected network of sensors that accumulate and exchange data within a warehouse. It helps the management to make data-backed decisions.

Source: Futurism Technologies

Why Use IoT in Warehouse Management?

Implementing IoT enhances the efficiency of inventory in warehouses and helps you to respond to customer demands quickly. It enhances the efficiency and accuracy of the logistics process to a great extent. IoT based warehouse management systems enable remote monitoring to be done, reducing the dependence of an organization on human labor to a great extent and minimizing operational costs.

8 Core Benefits of IoT to Warehouse Managers

Sensors are installed in all warehouse products and pallets for precise inventory tracking. Using IoT, warehouses can track goods accurately.

IoT improves overall operations by detecting the particular machinery that needs to undergo maintenance. It helps to avoid the risk of breakdown of important equipment.

IoT-enabled RFID (Radio-Frequency Identification) tags monitor inventory levels and share alters when specific products are low in stock. Inventory management, therefore gets automated and errors are minimized.

IoT technology can help you detect any type of suspicious activity. Warehouse managers can therefore perform real-time surveillance and enhance warehouse security.

IoT sensors monitor weather conditions like humidity, air quality, and temperature to make sure that goods are preserved in perfect working conditions.

Source: Volusion

Warehouse systems can enhance order fulfillment systems. After an order gets placed, the system will prioritize the picking of items automatically. It will guide workers to the correct location.

IoT enhances operations, minimizes waste, and enables better resource allocation, helping warehouses to reduce their operational costs. Lesser errors and waste along with optimized routes for goods and vehicles contribute to a more sustainable approach to warehousing.

IoT is most widely used in fleet management since trucks and other vehicles can use IoT devices like sensors to track actions and patterns to manage and run the fleet efficiently. For instance, companies can keep track of driver behavior and identify habits that cause higher fuel consumption.

Want to streamline your Warehouse Inventory Management process? Hire top mobile app developers in India to implement methodologies customized to your specific business needs.

Compliance With Regulations

Optimizing pallet space is essential both for asset positioning as well as compliance with regulations. Logistics companies must weigh their goods precisely to make sure that they stay within the allowed thresholds. The sensors used in the pallets eliminate the necessity to weigh cargo and avoid doing lengthy calculations.

AI-powered software can also enable staff to issue paperwork required by regulatory bodies precisely. They won’t miss any legal documents and the chances of fines caused by violation of regulations will also be reduced.

Source: NetSuite

The 17 Uses of AI Inventory Management In Warehouses

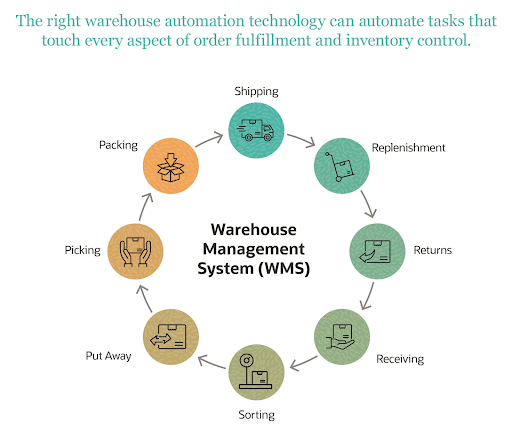

The use of AI inventory management solutions helps to transform operations and can replace people in certain roles, thereby minimizing errors and enhancing efficiency. This technology has changed how goods are handled and made processes more flexible than before.

According to a report by McKinsey, organizations are planning to increase investment in automation considerably over the next four years, up to 25% of their capital spending on average.

The use of AI is becoming common in warehousing. Some of the AI-powered solutions that are commonly being used in the industry include –

AI inventory management helps in real-time monitoring of stocks and aligns it with the present market trends to ensure the availability of products in inventory. Therefore, issues like overstocks or stockouts don’t crop up.

Using AI for warehouse management, you can analyze large datasets for optimizing resource allocation. It will help you to minimize costs and increase the speed of order fulfillment. Using AI inventory management solutions, you will be able to analyze large datasets to optimize resource allocation.

AI integration in warehouse management will help you anticipate market shifts through the use of historical data and market trends. This ability to make accurate forecasts enables warehouses to align their resources with precision.

Operators and quality control staff can rely on AI to receive feedback in real time. This will enable them to take the right measures before producing defective products. AI models can also figure out how to distinguish harmless irregularities from major defects and minimize the number of false alarms generated.

Operators and quality control staff can rely on AI to receive feedback in real time. This will enable them to take the right measures before producing defective products. AI models can also figure out how to distinguish harmless irregularities from major defects and minimize the number of false alarms generated, thereby saving both time and resources. The precision with which AI assesses products minimizes the risks of human errors.

Source: FasterCapital

Using AI in warehouse management can help you to enhance the order fulfillment process. You can use intelligent algorithms for analyzing historical data, predicting demand patterns, and optimizing picking routes. Therefore, the order fulfillment process will become more efficient and streamlined than before, and lead times will be reduced.

The predictive abilities of AI extend beyond inventory management and order fulfillment. Through accurate data analysis, AI can predict possible equipment failures and predict schedule maintenance. By doing so, it will not just ensure operational continuity but also reduce downtime and related costs.

The use of AI-driven sensors in warehouses ensures real-time visibility of all activities related to operations. These sensors not only monitor environmental conditions but also track the movement of goods as well as employee performance. Real-time data helps warehouse managers to make quick decisions and adapt to changing circumstances quickly.

AI algorithms analyze data related to demand patterns, turnover rates, and product dimensions to suggest optimal storage configurations. This improves store efficiency and ensures faster retrieval, ensuring overall operational agility.

Integration of AI-powered robotics has changed the way materials are handled inside warehouses. These intelligent machines are equipped with computer vision and learning abilities. They can also navigate complicated warehouse environments on their own. AI-powered robotics can streamline all aspects of the material handling processes with speed and accuracy.

AI can help businesses automate the replenishment process via purchase orders that are generated automatically. It also reduces manual labor by speeding up the ordering processes and increasing inventory accuracy.

AI helps to improve delivery routes by looking at a warehouse’s layout, including product location as well as order-picking tasks. It uses data collected for mapping out the most efficient picking routes. This reduces how far workers need to travel, improving productivity, enabling quicker fulfillment of orders, and reducing labor costs.

Another major benefit of AI inventory management is that it helps to constantly keep track of product demand and adjust where items get placed. Items that are picked more frequently are placed in a more accessible location. So, order pickers don’t have to walk a long way to find these items on the shelves.

It also helps to identify orders without overlapping items and grouping them to be picked in a batch. It enables orders to be placed in waves based on factors like priority, order size, and location. It uses visual cues to help pick-to-light and put-to-light order pickers to a location.

Implementing IoT sensors in trucks and other vehicles ensures efficient tracking of goods. You can use sensors to capture and exchange data. IoT enables remote handling of data across the entire network infrastructure. For instance, you can embed sensors in vehicles carrying goods to different locations.

There is software equipped with AI capabilities that utilize advanced algorithms to offer real-time insights into existing inventory levels. It helps warehouses to maintain their stock levels and ensure that there isn’t too much or insufficient stock. You can also use AI to analyze historical sales and seasonal trends data to offer highly accurate demand forecasts.

It is necessary to optimize the pickup of orders to ensure that products don’t get affected under any circumstances. You can rely on technologies like IoT and AI to ensure optimized pickup. Trucks are chosen based on the type of load that is to be carried. AI uses historical patterns and enables carriers to make decisions. Based on the type of goods to be transported, an AI-based model predicts the right truck for goods pickup. For instance, if you want to pick up sensitive goods that require special care, you can use IoT-enabled trucks for pickup.

These trucks can gather details like the temperature in which the goods have been stored, real-time product location, humidity during the delivery process, and truck data such as speed and fuel expenses. This data will be shared with logistics companies and product owners to ensure that the quality of products is maintained across the whole supply chain management process.

Sensors that are equipped in trucks can capture data such as crash incidents, the temperature under which goods are kept, and humidity. The real-time data collected by IoT devices will help logistics companies to track transit operations with precision.

AI can also help you to automate the stock maintenance process. Companies can maintain low carrying costs by having ample inventory to meet customer demands. You can use AI to generate purchase orders or restock requests when items become low to ensure there are no stockouts.

AI technology can also improve accuracy to match requests with picked inventory. Doing so will reduce the number of customers getting the wrong product or the number of items shipped. You can use AI to review details related to supplier performance, such as delivery accuracy and lead times. Your company can use the data for making decisions on current supplier relationships.

Conclusion

In the days to come, both AI and IoT will automate several manual tasks associated with warehouse operations and significantly improve efficiency. Logistics operations will therefore become smarter. Therefore, delays in pickup and delivery will soon become a thing of the past as more and more logistics companies adopt the use of AI and IoT in their day-to-day business operations.

AI technology will also improve accuracy to match requests with picked inventory. Doing so will reduce the number of customers getting the wrong product or the number of items shipped. You can use AI to review details related to supplier performance, such as delivery accuracy and lead times. Your company can use the data for making decisions on current supplier relationships.

How Can ROCKEYE Help to Create Customized AI Inventory Management Solutions?

At ROCKEYE, our AI-powered inventory management solution will help you to optimize stock levels, enhance customer satisfaction, reduce costs and streamline operations. From advanced reporting to tracking tradeable items and stock management, our AI-powered inventory management solution will help you handle all aspects of the supply chain management process with perfection.

Using our AI-powered inventory management solution, you will be able to efficiently manage the movement of items, organizing them by value, demand and priority. They can be classified as either tradable or non tradeable, use barcodes and implement standardized labeling.

FAQs

1. How Does AI Contribute to Transforming Warehouse Operations?

AI improves warehouse operations via predictive analytics, demand forecasting and inventory management optimization. It helps to make smart decisions, minimize errors, and enhances efficiency in tasks such as routing, picking, and packing.

2. How Does IoT Help in Modernizing Warehouses?

IOT sensors and devices help to ensure real-time tracking of inventory, equipment and environment conditions inside warehouses. The data is used for streamlining processes, preventing stockouts, checking equipment health, and ensuring optimal storage conditions.

3. How Do AI and IoT Work in Warehouses?

AI uses data collected by IoT devices to generate insights and make predictions. AI algorithms analyze IoT sensor data to predict maintenance needs of machinery or optimize placement of goods within a warehouse based on real-time demand signals.

4. What Are the Benefits of Integrating AI and IoT in Warehouse Operations?

Integration of AI and IoT helps to improve operational efficiency, accuracy, productivity and minimize costs and ensure proper usage of resources. It also enables warehouses to quickly adapt to the changing demands of customers and market trends.

5. Can AI Inventory Management Solutions Help in Real-Time Inventory Tracking?

Yes, AI inventory management solutions are proficient in performing real-time inventory tracking. They continuously monitor stock levels, trends and movements and help warehouses to make informed decisions and ensure that issues like stockout or overstock don’t crop up.

Ready to Unlock the Full Potential of Your Warehouse With AI and IoT?

Get in touch with the experts of ROCKEYE.

Request a Call