Now enterprise resource planning in supply chain management plays a crucial role in optimizing operations and reducing costs. An ERP system can increase data accuracy and simplify workflows by integrating various supply chain functions into a single platform. On top of this, it improves the overall decision-making process along with efficiency.

Businesses utilize ERP solutions to enjoy better inventory control, efficient procurement processes, and seamless communication between departments. However, there can be some challenges in its implementation. In this blog, you will go through its benefits, challenges, and best practices for using ERP for better results.

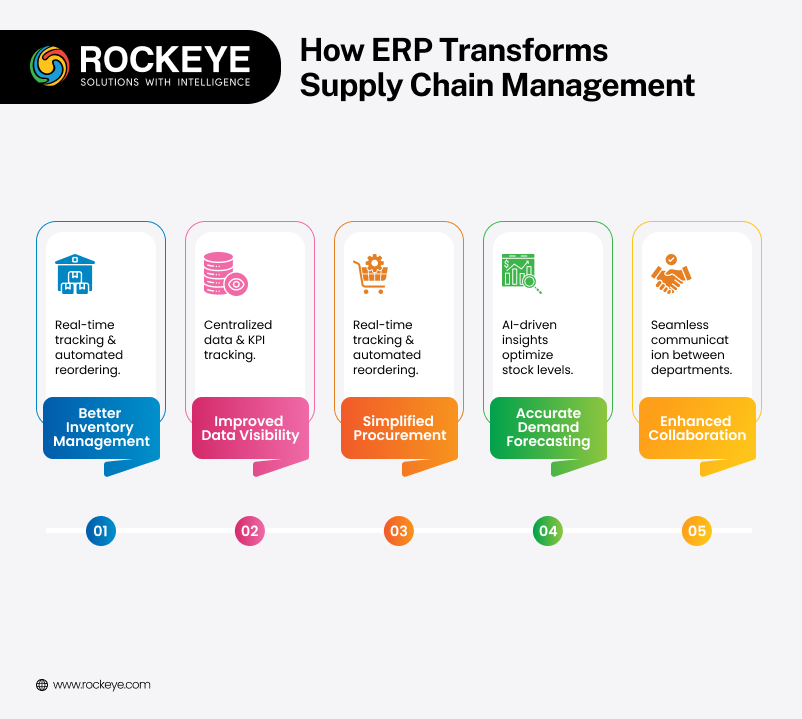

Benefits Of Using ERP In Supply Chain Management

- Better Inventory Management

Effective inventory management is important to meet customer demand without overstocking or stockout. ERP systems offer real-time tracking of inventory levels across multiple locations. It allows businesses to maintain optimal stock levels. Features such as reordering and demand forecasting help in reducing carrying costs and minimizing stockouts.

According to the report by Software Path, 33% of companies invest in ERP primarily to improve efficiency and gain better functionality.

- Improved Data Visibility And Analytics

ERP systems integrates data from various departments into a single source which improves the overall visibility across the supply chain management. This integration allows for better tracking of key performance indicators (KPIs). Also, the teams can identify the bottlenecks and make informed decisions to avoid them. According to a report by Panorama Consulting, businesses using ERP solutions enjoy better decision-making capabilities through better data access and insights.

- Simplified Procurement Processes

Automating procurement workflows is another major advantage of enterprise resource planning in supply chain management. ERP systems facilitate efficient handling of purchase orders, supplier evaluations, and contract management. Organizations can reduce manual errors, shorten procurement cycles, and negotiate better terms with suppliers by standardizing procurement procedures.

- Accurate Demand Forecasting

ERP systems utilize historical data and advanced analytics to improve demand forecasting accuracy. Businesses can align production schedules and optimize inventory levels by predicting customer demand trends. On top of this, they can prevent issues like stock outs or overproduction. This proactive approach leads to better utilization of the resources in the business. Also, they respond properly according to current market changes.

- Improved Collaboration And Communication

Integration of various business functions through enterprise resource planning in supply chain management increases the level of communication within a company. Different departments in the company like sales, finance, operation, etc., can access shared data. This high level of collaboration leads to synchronized efforts and cohesive strategies.

The unified approach makes sure that all the stakeholders are aligned with the end goals of the company. This further reduces the number of misunderstandings and increases overall efficiency.

- Regulatory Compliance And Risk Management

It is important to maintain compliance with industry regulations in supply chain management. ERP systems assist in monitoring compliance. They provide tools to document, report, and audit. Companies can use the tools to adhere to the legal standards. Also, they can prevent the risks linked with non-compliance like fines, penalties, and damage to reputation in the market.

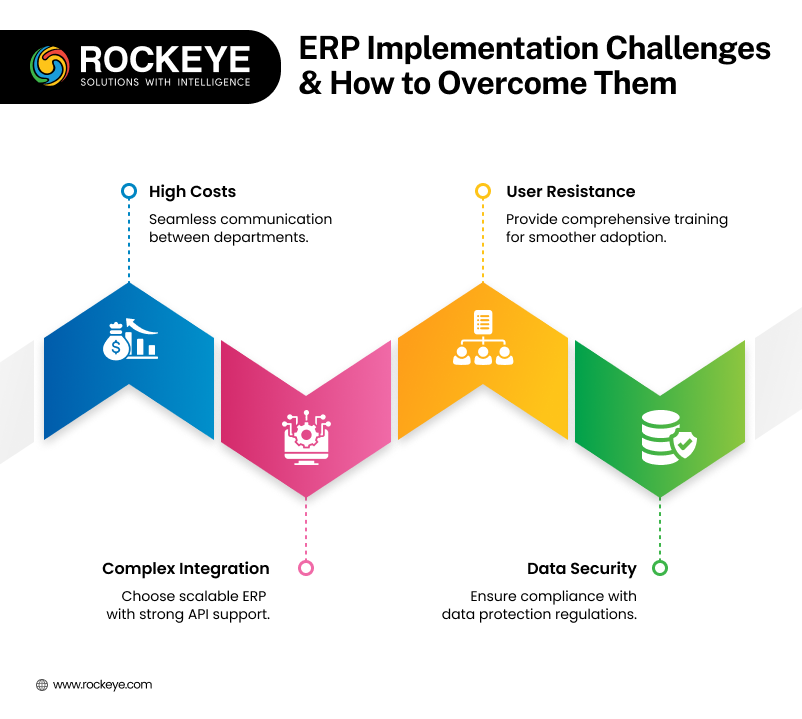

Challenges Of ERP In the Supply Chain Management

- High Cost of Investment

You must have a solid backup of funds to deploy an ERP system. It should be enough to cover the following things:

- Software licenses

- Hardware upgrades

- Consulting fees

- Training

For small and medium-sized enterprises, these costs of enterprise resource planning in supply chain management can cause a problem. Also, it may take some time to get a good return on investment through the solution.

- Complex process of integration

It can be difficult to integrate an ERP system with existing legacy systems as it can take a lot of time. There can be some compatibility issues during the integration process. You may have to customize some elements for proper functionality.

- User Resistance and Training

When you shift to a new ERP system, there can be some resistance from employees who are used to the existing processes. So, you have to invest in comprehensive training programs to counter their resistance. The training will familiarize the new system to the employees. They will be more comfortable using it which will increase their overall productivity.

- Data Security and Privacy Concerns

There can be some concerns about data security and privacy when you centralize sensitive business data within an ERP system. So, you must deploy tight security measures to protect against data breaches. Also, you have to maintain proper compliance with data protection regulations.

Ways To Use ERP In Supply Chain Management For Higher Productivity And Reduced Costs

- Automating Routine Tasks

ERP systems automate repetitive tasks like processing orders, updating inventory, etc. The automation reduces the manual errors and saves time. Also, it increases operational efficiency by removing paperwork and simplifying the workflows across departments. Employees can focus on strategic initiatives rather than spending time on administrative work.

Besides this, automation improves the consistency of the data entry process. It reduces the discrepancies in supply chain records. Businesses can integrate automation through ERP systems which will lead to improvement in productivity. It will reduce labor costs and increase overall supply chain performance.

- Implementing Just-In-Time (Jit) Inventory

Just-in-time (JIT) inventory management helps businesses maintain optimal stock levels by synchronizing inventory with real-time demand. ERP systems provide accurate tracking and automated restocking alerts. This reduces the risks of overstocking or stockouts.

JIT strategies improve cash flow and operational efficiency by minimizing storage costs and waste. Moreover, ERP-driven JIT systems allow businesses to respond quickly to fluctuations in customer demand. This allows them to enjoy a more cost-effective supply chain while maintaining consistent product availability.

- Improving Supplier Relationship Management

ERP solutions help businesses build stronger supplier relationship through:

- Better communication

- Automated contract management

- Real-time performance tracking

Businesses can monitor supplier reliability, negotiate better terms, and offer timely deliveries. A centralized supplier database helps them to streamline the procurement. This reduces the costs associated with delays or supply chain disruptions.

With improved transparency, companies can select and retain high-performing vendors. They can maintain the quality of raw materials or goods while optimizing supplier collaboration for long-term success.

- Utilizing Advanced Analytics For Decision-Making

Cloud Based ERP systems provide businesses with real-time data analytics. It helps the managers to make informed decisions about production, procurement, and logistics. ERP solutions predict market fluctuations by analyzing historical trends which further allows the companies to adjust their supply chain strategies.

Better analytics help to identify inefficiencies, reduce waste, and improve resource allocation. Predictive insights also enable businesses to forecast demand accurately which prevents unnecessary expenditures.

- Optimizing Order Fulfillment And Logistics

ERP solutions streamline the order fulfillment process through the integration of warehouse management and transportation planning. Businesses can manage logistics by automating shipping schedules and optimizing delivery routes. Also, ERP helps reduce lead times. This makes sure that the customers receive products faster while lowering transportation costs.

Businesses can follow a proactive approach by integrating supply chain visibility tools and minimizing delivery delays. Optimized logistics seamless coordination between warehouses, suppliers, and transportation networks. This raises the customer satisfaction level and reduces the operational costs for the businesses.

- Improving Demand Planning

It is necessary to have precise demand forecasting to avoid supply chain disruptions and unnecessary costs. ERP solutions use predictive analytics to analyze different aspects like:

- Market trends

- Historical sales data

- Customer behavior

They allow businesses to plan production schedules effectively. Companies can improve procurement processes, reduce wastage, and prevent stock shortages with better demand planning.

- Strengthening Compliance And Risk Management

ERP systems help your business to comply with industry regulations. You can track regulatory changes and maintain compliance with the safety, quality, and environmental standards.

Moreover, ERP-driven risk management tools identify vulnerabilities in supply chain processes. This further allows you to mitigate potential disruptions in real time. The improved level of compliance will raise the credibility level of your brand and reduce the overall legal risks.

Conclusion

Enterprise resource planning in supply chain management is an excellent option for businesses that are looking to improve efficiency and cut costs. You can use the power of automation to reduce costs and improve the overall communication in your business. It comes with several long-term benefits that outweigh its initial cost. ROCKEYE offers a next-gen suite of cloud-based ERP solutions that can transform your business. Call them to get all the details.

FAQs

- What Is The Role Of ERP In Supply Chain Management?

ERP integrates various supply chain functions into a single platform:

- Inventory management

- Procurement

- Logistics

This helps in increasing the overall efficiency and reducing the costs for your business.

- How Does ERP Improve Inventory Management?

ERP provides real-time inventory tracking, automated reordering, and demand forecasting, helping businesses maintain optimal stock levels.

- What Are The Factors To Consider Before Picking The Right ERP Solution?

Here are some important factors that you need to keep in mind while selecting an ERP solution.

- Scalability

- Industry-specific features

- Integration Capabilities

- Customization level

- Flexibility

- Security features

- Cost and ROI