Terminal Management Systems have become an integral part for today’s businesses across various industries. This is because in the current fast paced world, enterprises are looking towards gaining competitive advantage faster. From streamlining operations to processing transactions, Modern Terminal Management Systems enable advanced analysis and improved decision making.

Like others, the Oil and Gas industry is also undergoing transformation in its business processes to stay adaptable. According to Kings Research, the Oil and Gas Market size globally was recorded at 6, 705.68 billion dollars in 2023 and is expected to be around 6,923.33 billion dollars in 2024. It further predicted that by 2031, this value may go up to 8,917.40 billion dollars registering a CAGR of 3.68% from 2024 to 2031. These statistics indicate the vast expansion of this industry and the need for an advanced Terminal Management System to streamline the functions.

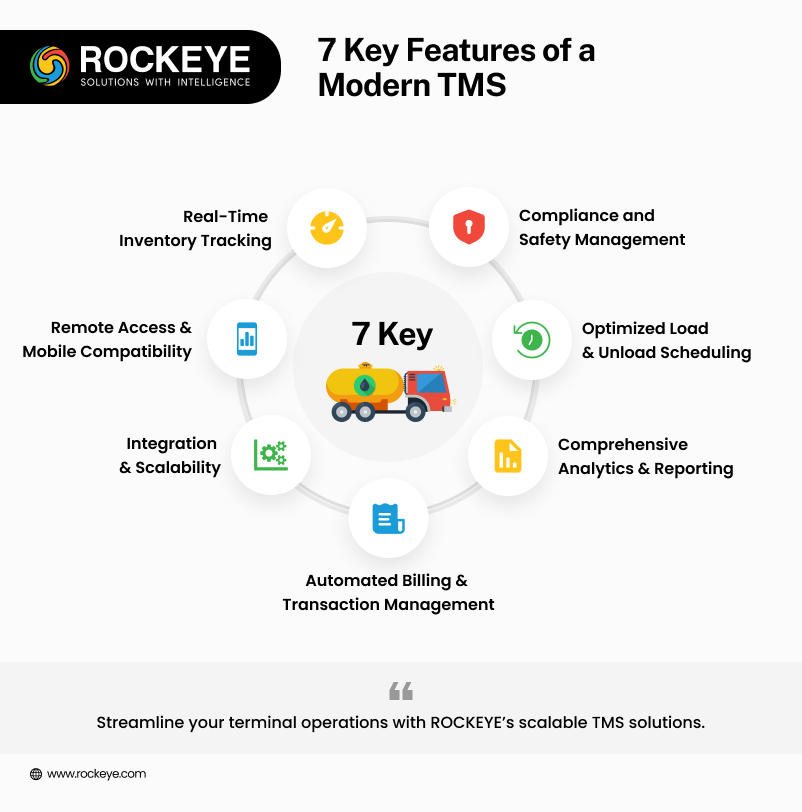

Through this blog you will have insights on 7 key features of a Modern Terminal Management System in the Oil and Gas industry.

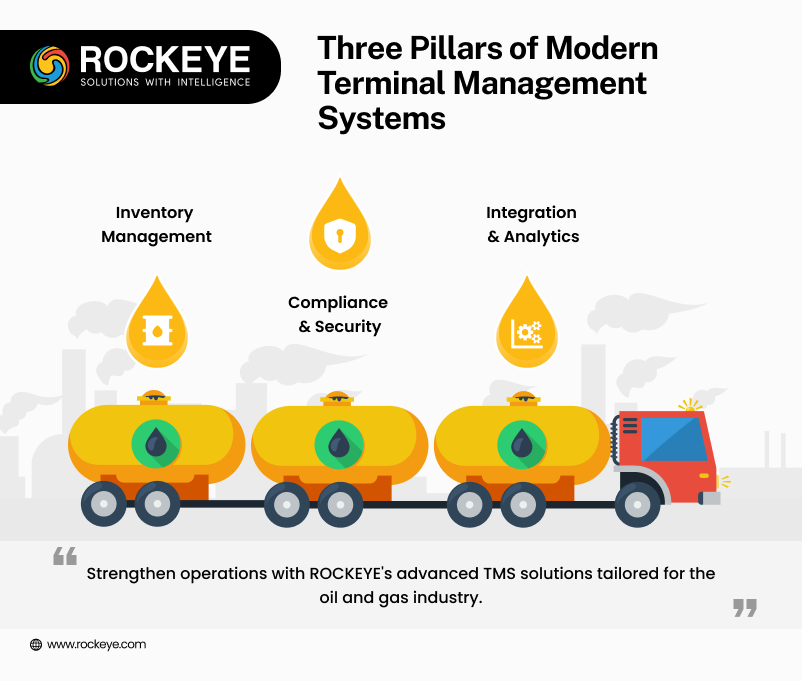

Terminal Management in the Oil and Gas industry is crucial to ensure regulatory compliance, efficient operations and profitability. Using Modern Terminal Management Systems, Oil and Gas companies can serve the increasing demands and reduce complexities seamlessly. From maintaining safety standards to reducing operational costs Terminal Management Systems or TMS helps companies to stay relevant and profitable.

Let us look at the 7 essential features of modern TMS solutions pertaining to the Oil and Gas industry.

Real Time Inventory Tracking and Monitoring:

This is one of the key features of modern Terminal Management Systems as it provides deep insights into tank capacity, stock levels and product movement. Advanced TMS solutions are equipped with intelligent sensors and automated measurement abilities to provide vital data related to density, volume, temperature and pressure. With real time visibility into inventory, operators can

- Optimize storage utilization and prevent product shortages

- Forecast future demands effectively

- Respond faster to fluctuations in stock level

Compliance and Safety Management

In the Oil and Gas industry, safety is a top priority. This is because in this space even minor negligence results in severe consequences. Utilizing effective TMS helps terminal operators to follow industry and environmental regulations. Here the key benefits lie in :

- Automated alerts to inform operators about unauthorized access and abnormal conditions.

- Regulated Compliance Monitoring to ensure that the terminal activities are in alignment with operational and environmental standards.

- Use of Incident Management Tools to identify safety breaches

Apart from enhancing safety, these tools prevent businesses from liabilities. Additionally it fosters compliance and promotes a safer work environment.

Optimized Load and Unload Scheduling:

By optimizing load and unload scheduling processes, a modern TMS ensures effective handling of products in and out of the terminal. This facilitates the operators to

- Automate and balance scheduling to avoid overbooking and reduce resource strain.

- Coordinate with transportation systems and align product movement via available resources.

- Improve turnaround times and minimize wait time for ships, trains or trucks.

With these features terminals improve customer satisfaction and maintain optimum asset utilization.

Comprehensive Analytics and Reporting:

With data driven insights oil and gas terminals optimize operations and identify areas for improvement. Modern TMS powered with smart reporting capabilities and advanced analytics provides intelligence on

- Operational excellence metrics like asset utilization and cycle times

- Financial performance indicators involving revenue generation and cost management

- Predictive maintenance insights to reduce downtime and prevent equipment failures

Using these analytics managers make strategic decisions faster. Moreover, they forecast demands and identify trends to ensure improvement and profitability in terminal operations.

Also Read: 9 Procurement Risk Management Mistakes and How to Avoid Them

Integration and Scalability

Both integration and scalability capabilities are pivotal in a modern TMS. Utilizing this oil and gas companies ensure that the business process fits seamlessly into the existing IT infrastructure. Main integration points involve ERP, Supervisory Control and Data Acquisition, and other digital platforms. Integrated and scalable TMS offers:

- Customizable interfaces to enable alignment with unique operational needs

- Hassle free data sharing across systems resulting in reduced information silos

- Scalability for future expansion without compromising the current operations

This feature ensures that the TMS remains flexible and relevant. It also empowers the TMS to deal with increasing operational complexities as the business flourishes.

Automated Billing and Transaction Management

A TMS with automated billing and transaction management facilities helps oil and gas companies to simplify the financial aspects of terminal operations. From streamlining invoices to making the payment process faster, it provides

- Automated and accurate invoicing for all transactions

- Transparent and clear audit trails to enable financial tracking

- ERP integration to manage compliance and financial records in an error free manner

This feature reduces manual billing tasks and in the process saves time. Also the automated transaction management accelerates the revenue cycle and improves cash flow and operational excellence.

Remote Access and Mobile Compatibility

Mobile compatibility and remote access are indispensable in a modern TMS because of their ability to provide 24/7 operational insight. Using remote access both the management and operators of oil and gas companies respond, manage and monitor terminal activities from any location. This improves control and flexibility. Key features here are:

- Real time access to and mobile friendly dashboards for terminal data

- Role based access control for secure remote performance

- Proactive alerts to notify stakeholders about occurrences of any critical issues

With mobile compatibility, the responsiveness increases. Moreover it ensures operational continuity even when resources are on the go.

Conclusion:

Adopting a modern terminal management system is no longer an option for the rapidly growing oils and gas industry. Equipped with features like real time inventory tracking, efficient scheduling, analytics, safety management, billing automation, and integration, an advanced TMS enables the terminal operators to enhance safety measures, accelerate productivity, streamline financial processes, and gain insights to drive profitability. From addressing the complex demands within the oil and gas industry to creating a safe operational environment, a purpose oriented TMS benefits both the business and its customers. Any oil and gas operator today looking to optimize efficiency requires a modern TMS due to its outcome oriented and measurable performance.

FAQ’S

- What is a Terminal Management System for the Oil and Gas industry?

Oil and gas companies use a Terminal Management System or a TMS to monitor, optimize and manage terminal operations. It is basically a software which enables tracking inventories, streamlining financial transactions, ensuring compliance and safety, and optimizing load and unload scheduling.

- How does real time inventory tracking benefit terminal operations?

With real time inventory tracking, oil and gas companies remain updated on stock levels. This presents shortages of products and overstocking. Last but not the least it also helps the operators to respond quickly and efficiently to fluctuations.

- Why is safety management critical in a TMS?

Oil and gas companies are always prone to risks even due to minor negligence. Hence safety management is vital for this industry. Using safety management tools companies ensure regulatory compliance, minimize risks, and protect the work environment and human resources. In this process it reduces the occurrence of liabilities and costly incidents.

- Can a TMS integrate with other systems?

Definitely, a modern TMS integrates with accounting software, ERP, Supervisory Control and Data Acquisition,. Via integration it promotes seamless data flow across departments. Thus it reduces manual tasks, eliminates human induced errors and enhances operational efficiencies.

- How does automated billing benefit terminal management?

Using automated billing oil and gas companies accelerate payment processing, save time, reduce manual invoicing errors, and offer a transparent audit trail. Thus it makes financial management accurate and effective.

- Is remote access in a TMS secure?

Remote access in a modern TMS is of course secure. It is designed with role based access control which implies that only authorized people can have access to sensitive data and process information. Oil and gas companies avail this feature to ensure seamless workflow even when the resources are not onsite.

- How does load and unload scheduling improve terminal operations?

Using optimized scheduling oil and gas companies, minimize wait times, reduce bottlenecks, and ensures resource availability when required. This improves customer satisfaction and turnaround times. In today’s fast paced world this features is highly beneficial to stay adaptable and profitable.

- Automated Billing

- Compliance Management

- Financial Management

- inventory tracking

- Load Scheduling

- Modern TMS

- Oil and Gas

- Oil and Gas Industry Trends

- Oil Terminal Software

- Operational Efficiency

- Predictive Analytics

- Real-Time Monitoring

- Remote Access

- Safety Management

- Scalable TMS

- Terminal Management Systems

- Terminal Operations

- TMS Features

- TMS Integration