Supplier relationship management and the value it has brought about in the supply chain process both for businesses and vendors alike have been grossly underrated.

A quick look at the present-day scenario would reveal that many of the issues surrounding supplier relationships stem from the rapid growth in technology and the breakneck scale of the global economy.

As such, buyers are compelled to work on new strategies they can employ to overcome challenges like efficiency, high costs, or the improvement of operations. But before getting into that, let’s look at what supplier relationship management is really about.

What is Supplier Relationship Management?

Also referred to as SRM, supplier relationship management is the organized and methodical approach of appraising contributions made by suppliers towards businesses and brands. Under such management, CPOs (chief procurement officers) engage in estimating which of the company’s suppliers stand to provide the best influence when it comes to the success of your business.

SRM also allows organizations to forge trust, open and genuine communication, transparency, and mutual support among their suppliers.

Coordination and cooperation are at their peak when there is a well-established relationship between suppliers and buyers. With such a system in place, companies are able to take a strategic approach to buy products and services and protect the supply chain from unmitigated risks.

Why Build a Relationship with a Supplier?

The foremost thought in a buyer’s mind is steady profit and efficiency. Aiding in this endeavor is the supplier with whom you need to build a durable, healthy relationship in order for things to run smoothly.

When you aim for mutual growth, supplier relationships could not only consolidate the supply chain by increasing operational value and furthering efficiency, but it could also lower costs incurred significantly. This is because you will not constantly be on the lookout for fresh suppliers who are bound to charge initial costs as you would have already formed a steady bond with your main source of supply.

Furthermore, in a durable supplier relationship, you stand to gain preferential treatment in terms of the availability of products, a considerable reduction in risks involved, and access to the latest technology and innovations.

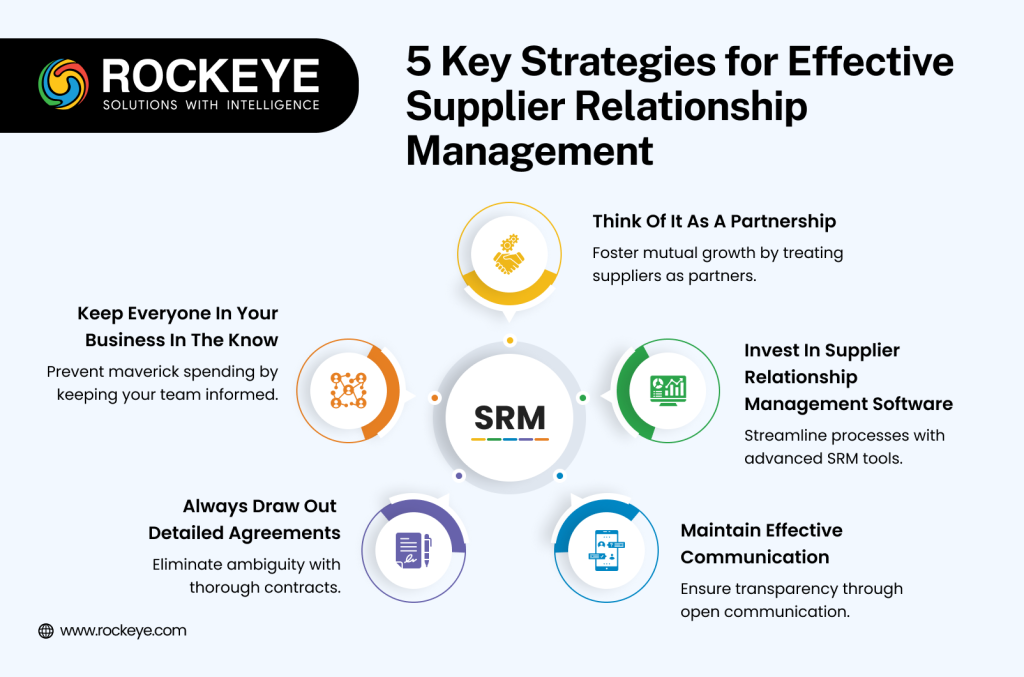

Supplier Relationship Management Strategies

1. Think of it as a partnership

If you want to maintain a long-lasting, trusting relationship that evokes loyalty and good camaraderie with your suppliers, you have to make them feel like they’re an important part of your business. By considering the relationship as a partnership and allowing them to be privy to company information such as processes and the launch of new products would make them feel valued. Also, make it a point to listen to their concerns and queries.

2. Maintain effective communication at all times

Ensuring that all channels of communication between your business and your supplier are open and strong is crucial to the smooth functioning of your organization and its growth. It allows both parties to be on the same page, encourages transparency and understanding, and builds trust between them. With such a formula in place, there is little room for error and communication breakdown.

3. Always draw out detailed agreements

Since sustaining a long-lasting supplier relationship is key to a successful SRM process, drawing up and maintaining agreements regularly becomes binding upon companies. You must also make sure that you obtain signatures from both parties. Pen down the expectations of both the bodies, like the description of a product or service, the cost, what the terms of delivery and payment are, etc. Collate all the points into a thoroughly documented supplier relationship agreement, thereby removing all possibilities of misgivings and ambiguity.

4. Keep everyone in your business in the know

Without letting everyone in your organization or procurement team know about the agreement between you and your suppliers, your business has every possibility of incurring extra costs and spending. Also referred to as maverick spending, reports suggest that by not keeping everyone in the loop and resorting to such a means of procurement, companies have spent about $ 530 billion in a year by way of additional costs.

5. Invest in supplier relationship management software

An efficient way of creating, processing, and tracking purchase orders, supplier management software is bound to make things easier for you. These kinds of software also allow you to manage all sorts of supplier information in one location. The following image depicts the key features of an SRM Software.

Also Read: 9 Procurement Risk Management Mistakes and How to Avoid Them

Challenges in Supplier Relationship Management

Although there are a number of reasons as to why you should embrace the supplier relationship management culture as a business, the process has its own list of drawbacks when it comes down to implementation. Here’s a look at the most important ones:

1. Cutting costs by all attainable means – What chief procurement officers and those responsible for executing supplier relationship management need to understand is that everything is not about reducing costs. You must always remember that SRM is a two-way street that seeks to benefit both buyers and suppliers alike. But if you focus all your strategy and tactics on reducing spending, you tend to lose sight of your company’s long-term goals and end up hurting your suppliers in the process as well.

2. The difficulty of equipping companies with the required skills – Traditionally, the procurement of products and services from vendors involved the skills of negotiation, understanding and identifying costs and risks, and analyzing the market. But contemporary SRM processes require far more competence and strategic knowledge, which many companies fail to adhere to. Equipping buyers and their team to develop leadership and change management skills and the ability to persuade and influence would come a long way in clearing this obstacle.

3. Lack of alignment between buyers and suppliers – As mentioned earlier, supplier relationship management is all about mutual benefit, and as such, when either partner seeks to undermine the other, it could pose a problem to everyone involved. A business that is keen on partnering with a supplier could be taken advantage of even if they’ve followed through on the basic guidelines of SRM. In other cases, organizations could approach suppliers through nefarious means, thereby hurting their sales. Such scenarios could probably be avoided by careful planning, discussion among team members, and setting clear goals and authentic vision.

The Future of Supplier Relationship Management Technology

Historic advancement of supplier relationship management relied heavily on a harmonized market wherein strategic partners worked on finding dependable, efficient, and practical solutions. Such a system worked well as the vendors were few, and they held a considerably high amount of the market share.

The start of this century saw many innovations and improvements in technology, including advancements in artificial intelligence, machine learning, cloud, and the creation of blockchain technology. By 2010, these technologies became well-established frameworks that showed promise.

Because of the many operational challenges that supply managers and companies face, the digital age has afforded them all kinds of tools and technologies to better their SRM strategy.

As a consequence, organizations are ready to incorporate artificial intelligence and machine learning into their supply chain processes. The advancement in these fields could mean better risk management and tools that could aid in the supplier selection process as well.

Supplier relationship management actions like the assessment of suppliers, auditing, collation of credit scores, and the like, allow supply managers to make decisions based on thorough research and select suppliers based on the data sets they gather.

Such kinds of upgrades make for a more anticipatory and perceptive selection of supplies, which, in turn, sets the basis for a supplier relationship that is bound to be fruitful. Artificial intelligence, therefore, has much to offer, and it is only a matter of time until this technology is used in more areas of the SRM process.

Also Read: Purchase Order vs Invoice: Key Differences and Why They Matter

How to Improve SRM Workflow

With an efficient supplier relationship management workflow in place, your business has every chance of becoming successful with an assured decrease in spending. Over time, every dime you’ve saved could amount to a considerably high amount of profit.

You can do this by ensuring that your company uses spend-management software that allows you to:

- Simplify SRM processes

- Allows company representatives and procurement officers to pursue definite guidelines for buying

- This, in turn, allows employees to concentrate on their designated responsibilities more freely

- You can constantly audit, analyze, inspect, and increase the value provided by your suppliers for your business

Wrapping Up

By improving your supplier relationship management process, you not only reduce spending by truckloads, but you also get to develop and further your relationship with your supplier. This will inevitably affect you positively in the long-run. Because a relationship built on trust, mutual respect, and growth is bound to yield results.

Although SRM has a long way to go, the current advancement in AI and machine learning is sure to boost and aid in bettering your business prospects.