Are you struggling to keep up with production demands? Do you find yourself constantly battling inefficiencies that eat into your bottom line?

If you’re nodding your head, you’re not alone. Many manufacturers face these challenges daily. Poor planning and scheduling can result in missed deadlines, additional resource and distribution costs, staffing issues, replacement materials, excessive waste, and unnecessary downtime—all of which contribute to unforecasted expenses. ERP for manufacturing businesses help you plan and schedule resources for your day-to-day operations, including advanced planning and scheduling, bill of materials, production, traceability, and increased customer satisfaction. A fully integrated ERP solution streamlines the process from customer orders through to distribution. Selecting the right ERP for your needs improves efficiency and productivity, reduces costs, and increases profitability. Selecting the right ERP for your needs improves efficiency and productivity, reduces costs, and increases profitability, as highlighted in this Accenture report on Smart Manufacturing in Life Sciences.

The benefit of using an ERP for Manufacturing

The biggest benefit of using ERP software for manufacturing is the integration of all operations into one seamless platform, tailored and flexible to your environment. When your sales, manufacturing, service, and finance functions work together seamlessly in real time, it maximizes efficiency.

Companies providing enterprise software can deliver ERP, BI, CRM, mobility, and web integration with multiple systems. Many companies initially believed ERP software was overly complicated and expensive for small to medium enterprises. Our aim is to provide cutting-edge technology at a lower price, ultimately driving efficiencies and profits for our customers.

Also Read: Ensure Optimum Savings Using A Vehicle Tracking System

We worked with a client who had several disparate systems and was struggling with a national warehousing and distribution model. After implementing our ERP for manufacturing, the company saw significant improvements in process efficiency, especially during peak times like Christmas and Easter. This made a substantial impact on their bottom line.

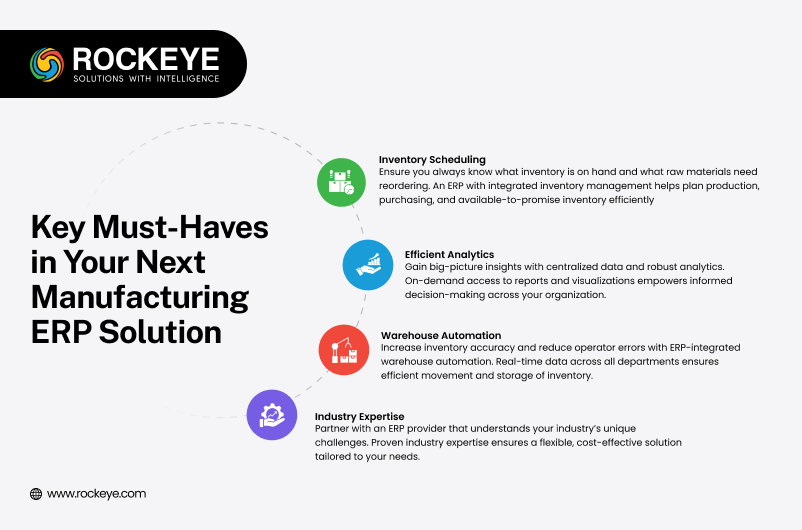

As a manufacturer, it is in your best interest to ensure these must-haves are included in your next ERP solution:

1. Inventory Scheduling

Do you find yourself asking what inventory is on hand, what raw ingredients need reordering, or when you need to factor in lag times for purchase order delivery dates? A must-have for all process manufacturers is an ERP solution that provides integrated inventory management. Your ERP system should help you factor in all supply, demand, and forecasted requirements through MRP (Material Requirements Planning). This will assist in planning production, purchasing, and available-to-promise inventory. With the right information, you’ll receive accurate recommendations for production and purchasing schedules, allowing for more efficient and effective use of your resources and capital.

2. Efficient Analytics

Gaining big-picture insight into your manufacturing operations is essential to staying competitive in your marketplace. With all of your company’s data stored in one centralized ERP database, reporting becomes easy, effective, and efficient. Modern analytics and business intelligence (BI) programs provide robust data reporting with interactive visualizations and analysis accessible from any device, anywhere in your business. Data is broken down into smaller, more manageable parts, with the ability to graph, sort, and drill into the numbers. This provides on-demand access to the information you need to make informed decisions quickly and easily share this critical information across your organization.

3. Warehouse Automation

Access to real-time inventory numbers and data accuracy is a top concern for manufacturers. An ERP system with warehouse automation can help control the movement and storage of inventory within your company and the supply chain through the use of barcoding. With fewer hands-on procedures and less operator error, the accuracy of transactions—such as purchase order receipts, inventory transfers, and physical inventory counts—is increased. This inventory transactional data is available immediately across all departments of the company.

4. Expertise in Your Industry

Checking off all the boxes for your manufacturing ERP system is just the first step in your selection process. You likely don’t want to be a test case for an ERP provider looking to expand its vertical reach or be subject to the whims of a support staff lacking best practice knowledge in your industry. Instead, look for a partner with time-tested knowledge of your industry and an ERP software designed to deliver functionalities uniquely suited to process manufacturers.

An experienced ERP provider understands the challenges your industry faces and builds flexibility into the software to handle upgrades efficiently and cost-effectively. They will also have a proven plan for ERP implementation and recommendations to utilize additional features in the software, which you may not have originally planned.

For over three decades, ROCKEYE has been designing, developing, and distributing ERP software to process manufacturers. We understand that every manufacturer and industry is unique. We’ve seen how companies that invest time and consideration into selecting the right ERP provider have inevitably experienced a greater return on their investment.